J. Casale - W2NI

Semi-Automatic Morse Transmitter Adjustment and Operation

Western Union Telegraph Company, July 23, 1915

The following is probably the earliest set of instructions for adjusting a semi-automatic Morse key. (Bug)

It was published by the Western Union Telegraph Company in a Traffic Circular (No. 44), dated July 23, 1915,

which reads as follows :

The results obtained by a series of sending-machine tests warrant the following conclusions :

1. Utility of Sending Machines - A sending machine in good condition, properly adjusted and competently handled, will carry reliably on all workable circuits without the changing of any adjustments save that which regulates the speed.

2. A General Principle - Changing the rate of vibration varies the lengths of both dot and space proportionately, while changing the relation of the dot-contact points increases one at the expense of the other.

3. Light Signals - If a receiving operator states that the signals are light, and the circuit cannot be improved, the remedy is to lengthen the dots by reducing the speed of vibration, not to change the relation of the dot-contact points.

4. Heavy Signals - If a receiving operator states the signals are too heavy, and the circuit cannot be improved, the remedy is identically the same as in (3), namely reducing the speed of vibration, as that will increase the length of the spaces.

The adjustments of semi-automatic keys are both mechanical and electrical, and the examinations should be made in that order.

Mechanical Examination and Adjustment:

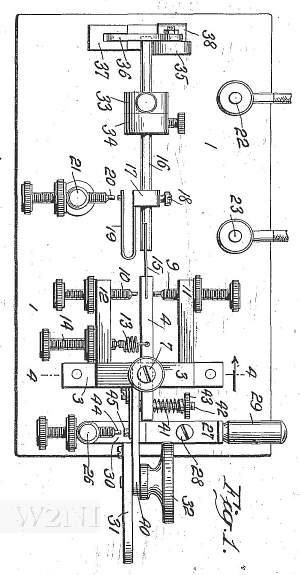

Drawing from Horace G. Martin's

(Added for a reference)

|

2. Springs and Lever Action - See that the springs are neither too weak to act nor too strong for comfort, and that the lever is not held too tightly by the trunnion screw. The lever should move easily, yet without wobbling.

3. Contact Points - File both the dot and the dash contacts smooth, and make the contact surfaces parallel when they meet.*

4. Adjustment of Dot-Contacts - Turn the top-screw on the same side of the machine as the deadener till the reed rests against the deadener without pressure. Clamp the stop-screw. With the reed in this position, the distance between the dot contacts should be one-sixteenth of an inch. If it is not, turn the dot-contact screw until it is, then clamp the screw. Now, by means of the other stop-screw, i.e., the one on the same side of the machine as the stationary dot-contact post, move the reed until the two dot-contacts meet without pressure when the reed is moved slowly by the handle. This adjustment may be slightly modified by the succeeding operations, but this modification has been taken into account in the instructions just given.

Electrical Examination and Adjustment:

1. Resistance of Machine and Cord - Measure the resistance of machine and cord, first, through the switch; second, through the dash-contacts; third, through the dot-contacts when the two points are pressed together by the hand. The total resistance in all cases should be less than one ohm.

2. Mil-Ammeter Adjustment - Place the machine in series with the mil-ammeter and one 150 ohm relay on a local circuit with a current of between 40 and 60 milliamperes. A way circuit will not do. Be sure that the machine rests on a horizontal base. Make groups of six dots each at a moderate rate of vibration, allowing time between the groups to permit the needle to return to zero. By "moderate" rate of vibration is meant a speed corresponding to that of a hand-sender, sending about thirty-five messages an hour. Neither a high rate of vibration nor a low rate will give the best results. The highest milliammeter reading for each group of six dots should be two milliamperes less than one-half the reading on a closed key. If this is not the case with the instrument being tested, turn the dot-contact screw until this reading is obtained, then clamp the screw. Repeat the dotting process to make certain that after clamping the position of the dot-contact point it was not changed.

Summary - When the reed rests against the deadener, the distance between the dot-contact points should be one-sixteenth of an inch, and when a group of six dots is made, the highest milliammeter reading should be two milliamperes less than one-half the reading of a closed key.

Note - The distance between the dash contacts does not affect the carrying power of the machine. It may be just sufficient to enable one to see clearly between them. One sixty-fourth of an inch is ample.

Approximate Adjustment - An approximately accurate adjustment may be obtained by the mechanical examination and adjustments without the electrical measurements.

*The use of a file may raise eyebrows for some but it was commonly used at that time to fix pitted contact surfaces. Also note that these early instructions were for keys used on a variety of telegraph circuits, including circuits where the keying pulled-in armatures of distant repeaters or armatures of local polarity-changing relays used for multiplex service. Heavy and light signaling/keying errors on these circuits were frequently caused by an improperly adjusted transmitter.

73, John W2NI

Return to the Horace G. Martin home page

Back to the Telegraph-History home page